Science & Technology Thrust 2 (STT2)

Material Design, Processing, and Characterization for Laser-Based Metal 3-D Printing

STT2 Challenges

An incomplete understanding of:

- Laser interaction with the powder feedstock.

- Dynamics of laser-induced melting and melt coalescence.

- Microstructure evolution during re-solidification including grain growth.

- Possible segregation of impurities and alloying elements to grain boundaries and boundaries between successively melted and re-solidified regions.

- Residual stresses and post-printing heat treatment.

Three Focus Areas

- Powder Synthesis

- Laser Powder Bed Fusion (PBF) 3D Printing

- Hierarchical Modeling

Powder Synthesis

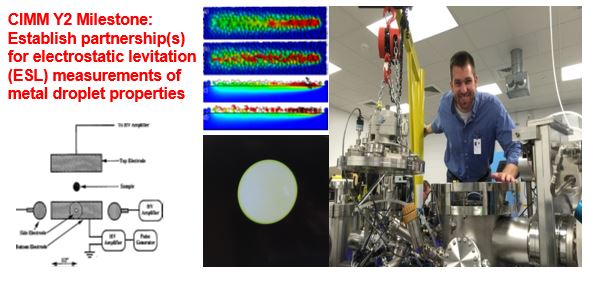

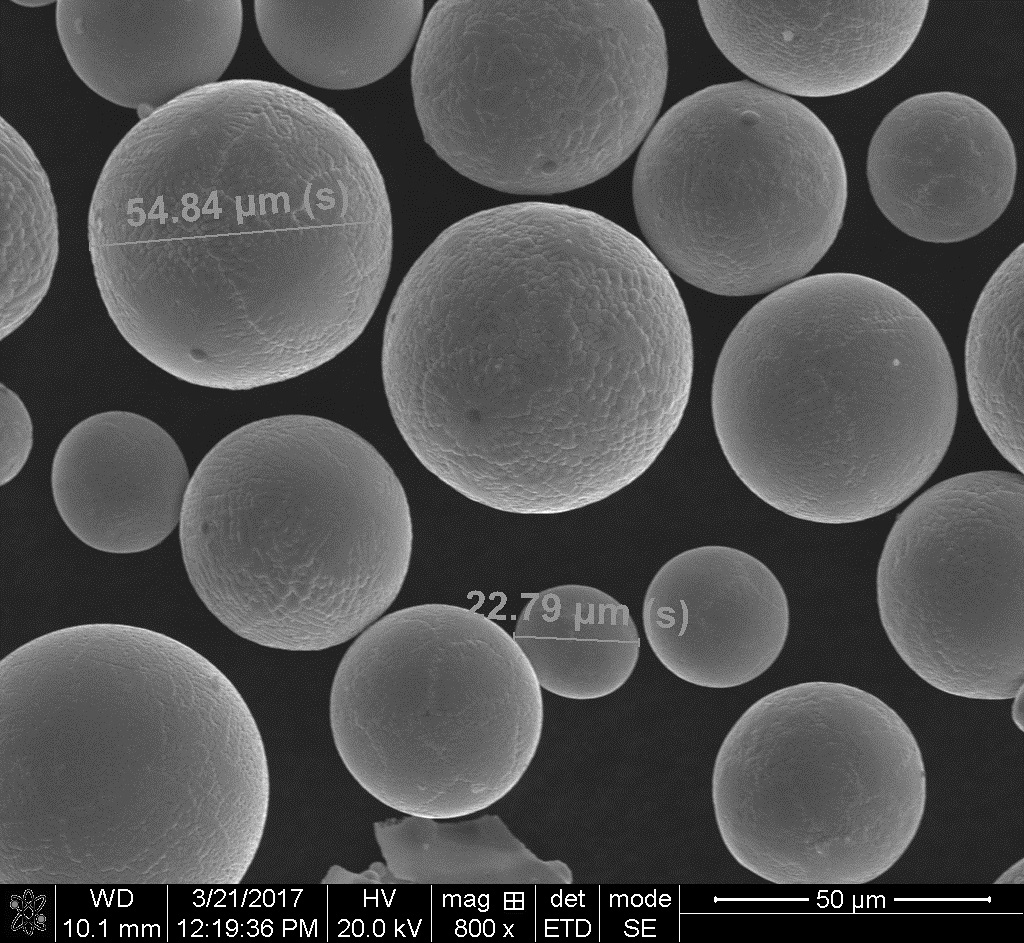

- Goal: Understand the influence of relevant thermophysical properties of metallic liquids on custom powder synthesis and Laser PBF printing processes.

- Objectives:

- Acquire powder synthesis capabilities.

- Study the powder synthesis process.

- Investigate thermophysical properties of metallic liquids.

- Investigate the influence of powder and liquid characteristics on 3D printing parameters.

Research and Demonstration Project Examples

Thermophysical Property Measurements (Electrostatic Levitation: ESL)

Powder Synthesis Using Rotating Electrode Technology

Average compression flow stress vs. Copper layer thickness.

Average shear flow stress vs. Copper layer thickness.

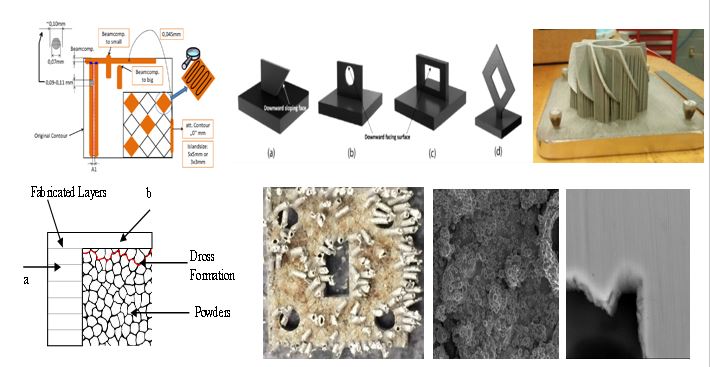

Laser Powder Bed Fusion (PBF) 3D Printing

Setup and use of additive manufacturing equipment based on Laser Powder Bed Fusion (PBF) technology towards the development of 3D printing in specialty alloys, such as high-entropy alloys.

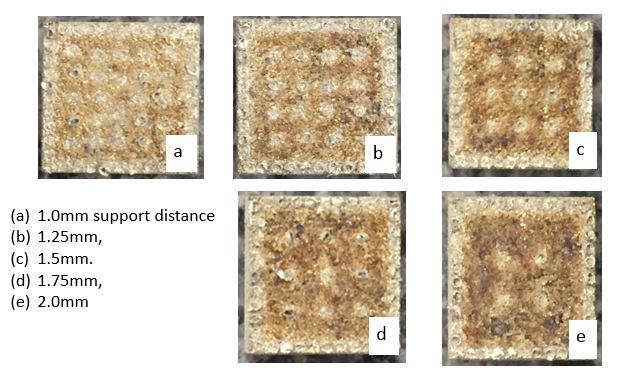

Dross Formation Mechanisms and Impact for Laser Powder Bed Fusion Technology

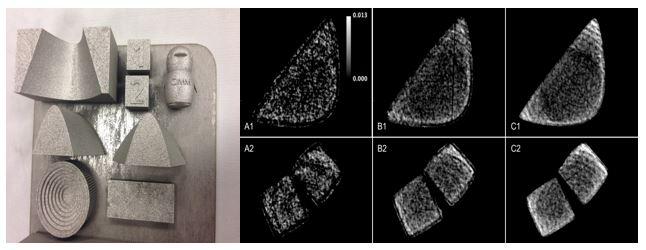

Porosity Imaging of Laser Powder Bed Fusion (PBF) Outcomes With Spatially Resolved Small Angle Neutron Scattering

Defect Analysis of Laser Powder Bed Fusion (PBF) 3D-Printed Parts By Using Positron Annihilation Spectroscopy

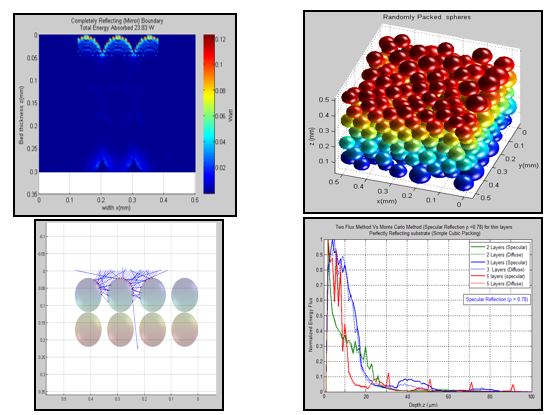

Radiation Heat Transfer in Powder Beds

Simulations are conducted to explore rediation heat transfer effects on the regional temperature field for Laser Powder Bed Fusion (PBF) applications. The heat transfer and ensuing thermal gradients play a significant role in determining both the dimensional and structural integrity of 3D printed metal parts.

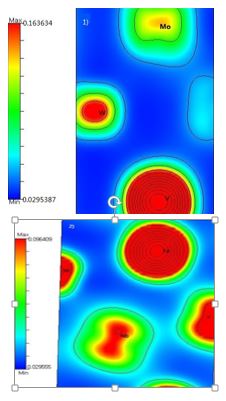

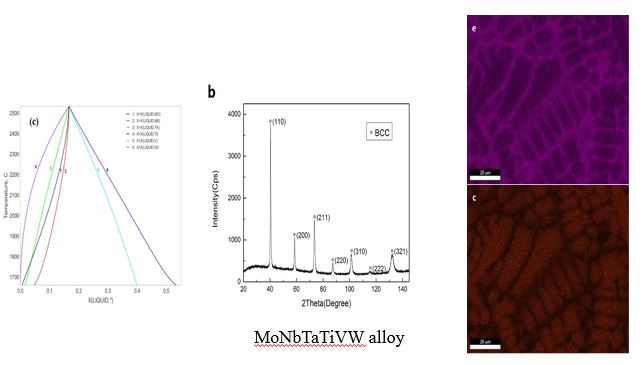

Density Functional Theory (DFT) Modeling of High Entropy Alloys (HEA) Intended for 3D-Printing Applications

The bulk modulus of a MoNbTaTiVW High Entropy Aalloy (HEA) is calculated along with the Bader charge of each composing element. Charge density contours are calculated to show electron density surrounding certain atoms within the High Entropy Aalloy (HEA), in order to investigate the nature of the bonding taking place during the alloy’s formation.

Besides major metallic bonding in the bulk alloy, weak partial covalence bonding are found at Mo-Nb, Nb-Ta, Nb-V, Ta-V and Mo-Nb interatomic bonding.

.

High Entropy Alloy Development

CALPHAD simulation and experimental testing of a MoNbTaTiVW High Entropy Aalloy (HEA) .

.

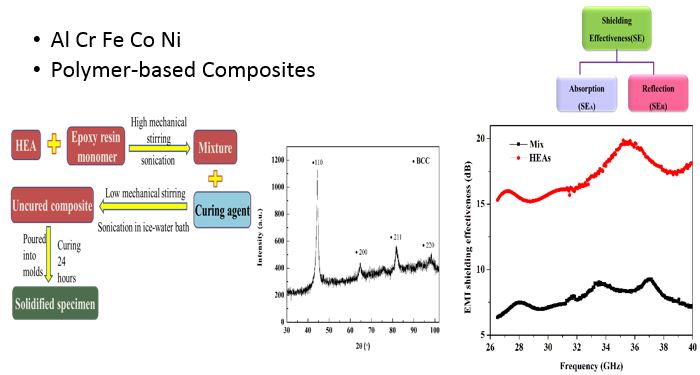

Electromagnetic Interference Shielding Effectiveness of High Entropy Alloys (HEA)

Application of a AlCrFeCoNi High Entropy Aalloy (HEA) towards improving the electromagnetic shielding effectiveness of polymer-based composites.

.

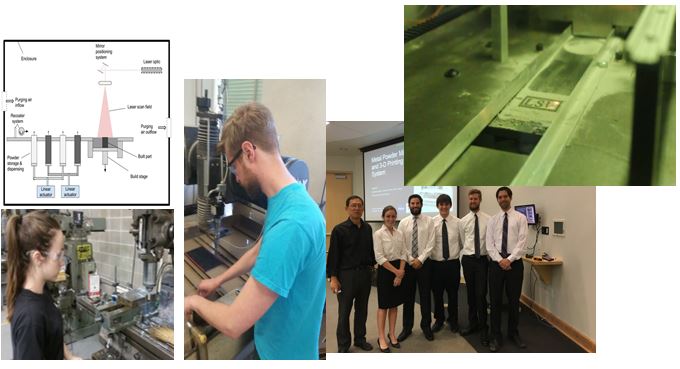

LSU Capstone Design Project: A Novel Powder Feeder for 3D Printing Based on Laser Powder Bed Fusion (PBF) Technology

A custom, open-source 3D Printer for metals based on Laser Powder Bed Fusion (PBF) technology was developed by a group of undergraduates at LSU under the Capstone Design Program. This open-source metal 3D-Printer enables research into the effects of operating parameters for novel alloys.

.